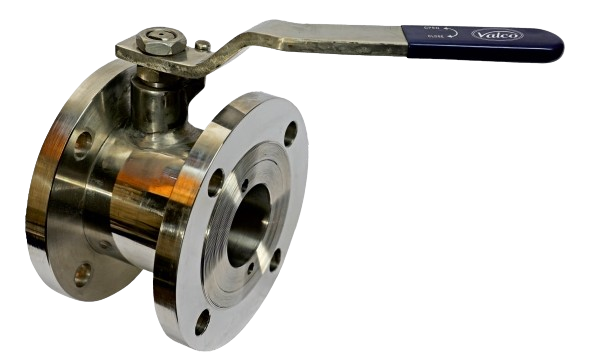

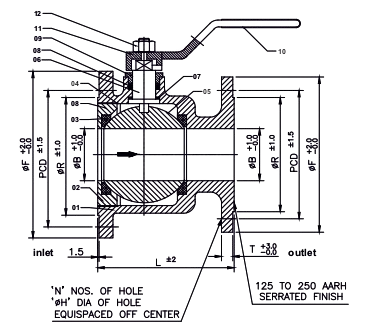

Flush Bottom Ball Valve

Technical Data

| Manufacturing standard | Flanged End | Inspection and Testing Standard | Face to Face |

|---|---|---|---|

| BS 5351 / BS EN 17292 | ASME B16.5. | API 598 / BS EN 12266-1 | ASME B16.10 |

| TEST PRESSURE | PSI | BAR | |

|---|---|---|---|

| HYDRO | SHELL SEAT |

450 300 |

30 20 |

| AIR | SEAT | 100 | 07 |

| S.NO | DESCRIPTION | MATERIAL |

|---|---|---|

| 1 | BODY | S.S 304 / S.S 316 / S.S 316L |

| 2 | CONNECTOR | S.S 304 / S.S 316 / S.S 316L |

| 3 | BODY SEATS | PTFE / GFT / CFT |

| 4 | BODY SEAL | PTFE / GFT / CFT |

| 5 | BALL | S.S 304 / S.S 316 / S.S 316L |

| 6 | STEM | S.S 304 / S.S 316 / S.S 316L |

| 7 | STEM SEAL | PTFE / GFT / CFT / GRAFOIL |

| 8 | GLAND PACKING | PTFE / GFT / CFT / GRAFOIL |

| 9 | GLAND BUSH | S.S 304 / S.S 316 / S.S 316L |

| 10 | SLEEVE | PVC |

| 11 | LEVER | S.S 304 / S.S 316 |

| 12 | STEM NUT | S.S 304 / S.S 316 |

Notes:

-

The Handle will be at 45 deg unless specified

-

Valves of Higher sizes & other MOC also available upon request.

-

Unless specified,Valves upto 2” will be with solid ball and above 2” will be hollow

-

Reduced Bore / Port available on request.

-

Wrench/Pipe Handle Available on Request.